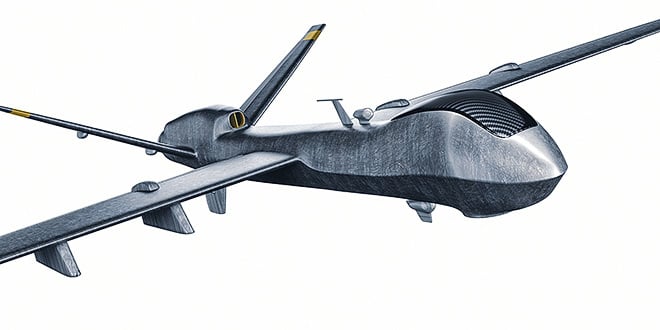

Advanced simulation for aerospace & defence plastics

From fibre orientation to PEEK: mastering high-performance moulding

Moulding for strict tolerances, high temperatures, and impact resistance is no mean feat.

Holding shape when things get heated

Composite materials, complicated moulding

Guaranteeing impact resistance & durability

The challenge of moulding high-performance plastics

Holding shape when things get heated

Composite materials, complicated moulding

Guaranteeing impact resistance & durability

The challenge of moulding high-performance plastics

Engineering reliability under extreme conditions

The holistic Cadmould simulation ecosystem addresses key challenges faced by makers of demanding aerospace and defence parts. From fibre orientation in anisotropic materials to moulding of heat-resistant plastics, it drives informed optimization of all aspects of process design.

Stay in shape—even at 30,000 feet

Fibre-reinforced? Design it right.

Where precision meets protection

High performance, high demands

Insights, innovations in injection moulding, webinars, and events.

Loreum ipsum, innovations in injection moulding, webinars, and events.

-

Complex part geometries requiring precise moulding techniques

-

Stringent quality and safety standards that demand high accuracy

-

Weight reduction initiatives to enhance fuel efficiency and sustainability

Real results. Trusted voices.

Customer stories and testimonials show how simulation turns challenges into measurable improvements.

60% lighter, 100% reliable

Through fast simulation-driven iteration, HellermannTyton engineered a charging socket holder that combines lightweight design with uncompromising accuracy.

Stacking adapter reimagined

How Plaston and Gollmer perfected a multi-brand toolbox connector with Cadmould and Varimos AI.

Getting canister lids right the first time

By combining simulation and modern measurement, Bergi-Plast improved closure quality, reduced scrap, and accelerated time-to-market.

We’ll connect you with the right expert!