Customer Stories

Discover How Companies Are Revolutionizing Their Processes with Cadmould Flex

60% Lighter, 100% Reliable

Automotive & Mobility

Electronics & Semiconductors

Injection Molding Optimization

Through fast simulation-driven iteration, HellermannTyton engineered a charging socket holder that combines lightweight design with uncompromising accuracy.

It's Good To Be Good, But It's Better To Be Better

HellermannTyton strives for true excellence. Customers know that they deliver the very highest quality and efficiency standards. As a result, HellermannTyton is routinely involved in the most ambitious customer projects, where rigorous quality standards must be met on tight timelines, while managing cost. The question is, how do they do it? The answer, it turns out, is multi-faceted. HellermannTyton combines a culture of excellence with a pioneering way of working. The result is a simultaneous engineering approach, supported by cutting-edge simulation technology. In this article, we will focus on how this culture of excellence and way of working are reflected in the design of plastic injection-molded parts. We will illustrate this way of working using an example: a charging socket holder, designed for a premium sports car manufacturer.

Working Together, Not One After the Other

Hagen Spiess, head of product development, explains the underlying philosophy: “We take a simultaneous engineering approach. This means we make sure that our injection molding teams are cross-functional. The work is organized by customer and product, not by department. We ensure that the part engineers, mold engineers, machine setters, and quality managers in a project work together, rather than one after the other.” Thus, one of the core principles is a front-loaded and cross-functional way of working. At HellermannTyton, “downstream” team members who operate the machines and measure product quality are already involved “upstream,” during part and mold design. Amadeus Langeloh, one of the key team members who focuses on part design, explains, “This is actually crucial. It helps us avoid predictable mistakes because we’ve reflected on manufacturing concerns early on, before we physically build the mold. It also increases buy-in from the entire team because everyone has a chance to influence the design. The result is that we need fewer corrections after the mold is built, and the issues that remain are usually less expensive to fix.”

Pictured from left are HellermannTyton's Hagen Spieß, Head of Product Development; Amadeus Langeloh, Design Engineer; and Oliver Rühmkorf, responsible for Product Development and CAD Administration.

In fact, the superior combination of accuracy and speed, enabled by Cadmould’s proprietary 3D-F simulation algorithm, is one of the main reasons why HellermannTyton works with Cadmould.

Amadeus Langeloh

Design Engineer

Digital Tools to Support Cross-Functional Work

This approach is underpinned by smart use of simulation technology. The simulations predict and visualize results before you incur the cost and time investment of building the real mold. The visualizations are used as a communication and discussion tool to evaluate different design options. The results facilitate decision-making in the cross-functional product teams because they show the consequences of different options. “This way, we can test and discuss different options digitally. It’s cheaper and much faster to modify a virtual design than it is to change a physical mold made of steel.” Now we turn to the component example mentioned above.

The Goal: Reduce Part Weight by Substituting Metal With Plastic

In this project, HellermannTyton worked on the charging socket holder for a premium sports car. Specifically, the goal was a weight reduction of more than 50%, while continuing to meet all functional, geometric, and stability requirements. In electric vehicles, weight is particularly crucial, since less weight means increased range.

Challenges: Stability And Geometric Accuracy

“A weight reduction can of course be achieved by replacing the metal construction with a fiber-reinforced plastic construction. The challenge, then, is to make sure the stability and precision requirements are met with this different material,” explains Amadeus Langeloh. “Stability is particularly crucial for this part because it can be subject to sudden strong forces—for example, if a user trips over the charging cable.” Furthermore, geometric accuracy is essential. Since the part connects the charging socket to the chassis of the vehicle, it needs to conform perfectly to both the socket and the connection points on the chassis. This means shrinkage and warpage need to be anticipated and managed.

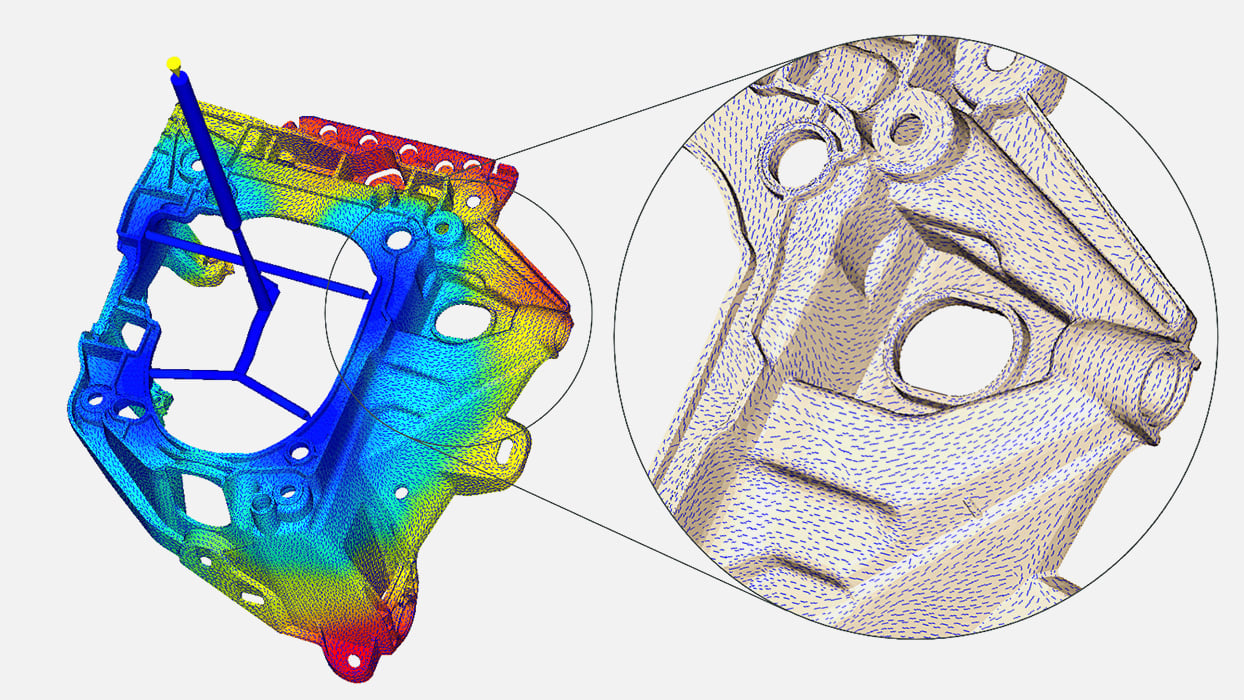

Principal fibre orientation

To evaluate its mechanical properties, the fiber orientation results of the Cadmould Flex fiber feature were analyzed using FEM software.

Simulating to Optimize Geometry and Mechanical Properties

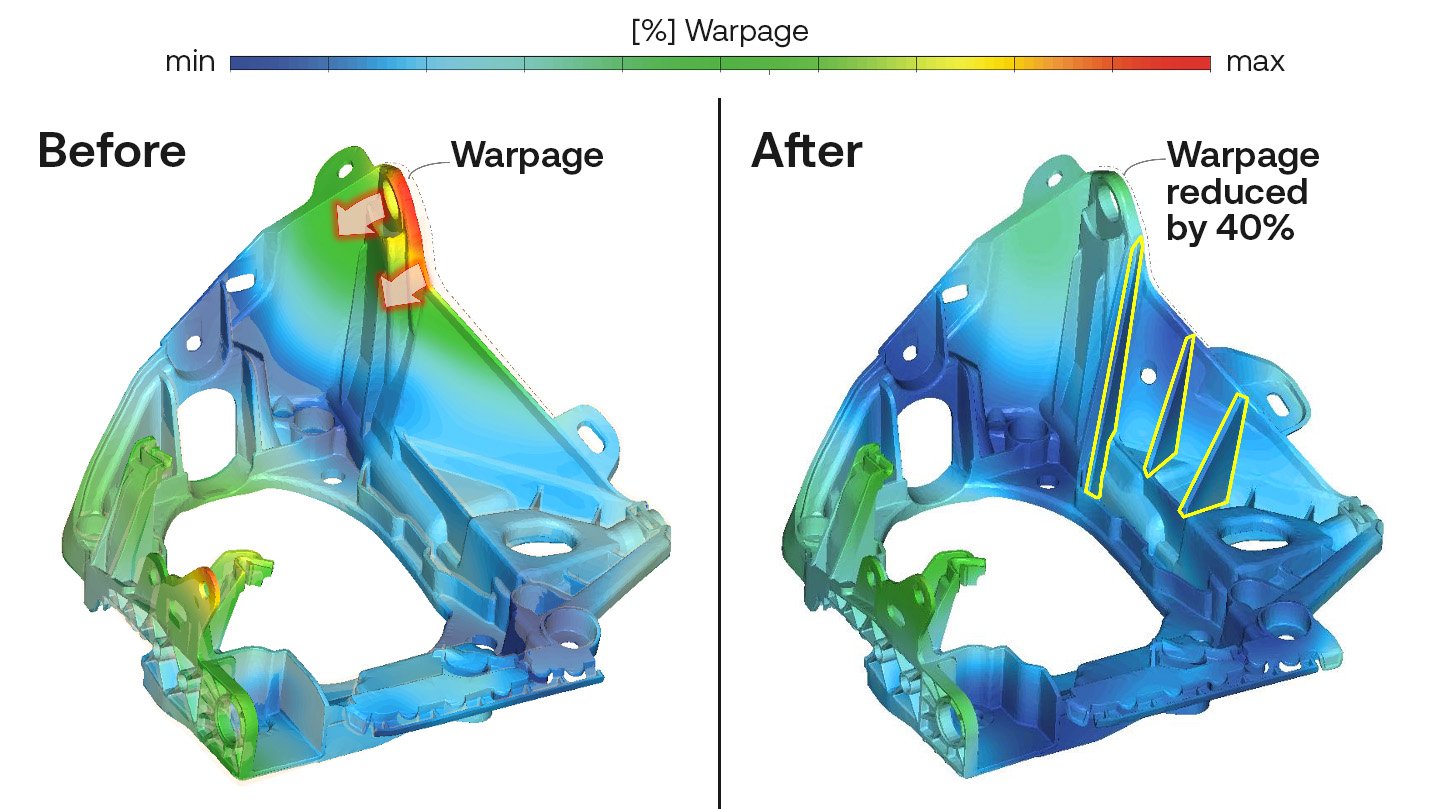

To optimize for these two challenges, HellermannTyton deployed a combination of plastic injection molding simulation and finite element method (FEM) simulation. Amadeus Langeloh, who led part design for the project, worked closely with the mold maker on the design of the cooling system. He also convened cross-functional meetings with his machine setting and quality management colleagues to discuss the main issues. To help achieve the mechanical robustness requirements, a material with a high share of glass fibers was chosen. HellermannTyton used SIMCON’s plastic injection molding simulation, Cadmould, to evaluate the location of weld lines and compute fiber orientation. Cadmould’s shrinkage and warpage simulations of the initial part design, however, showed that there was significant warpage at the connection points. Warpage in these locations is unacceptable, because this is where the part connects to other parts of the vehicle. To find a better solution, Amadeus Langeloh designed a few alternative rib structures, as well as special mold cores with very high thermal conductivity (copper/beryllium alloy), to reduce warpage in the critical part connection areas. These variants were simulated using Cadmould, in order to check their effect and pick the best solution. With this combination of designing and then testing variants in simulation, a design could be found that avoided the warpage.

Cadmould enabled HellermannTyton to rigorously evaluate the shrinkage and warpage effects across various design iterations. Through this systematic testing of multiple alternatives, they successfully refined the part design, incorporating several geometric modifications—notably the ribs, highlighted in yellow. This optimized design perfectly satisfied both the mechanical performance and geometric specifications.

Always Simulate Variants

This highlights a key principle for successful simulation: never simulate just one variant. It’s better to leverage the speed and agility of simulation to systematically test multiple design variants and choose the best option. Product developer Oliver Rühmkorf explains: “It’s important to avoid tunnel vision if you want the best results. Don’t get too stuck on your initial design—try out a few alternatives. Iterate. Use simulation as a tool to evaluate multiple options, not just to confirm or verify a single design choice. By exploring many variants, simulation can help you have better-informed, insightful, and constructive discussions with your colleagues!”When used correctly, simulation becomes a valuable tool for identifying better alternatives and improving cross-functional decision-making. Of course, to achieve these benefits, you need to run multiple simulations. As Amadeus Langeloh points out, “It’s critical that your simulation software is fast enough to run multiple simulations quickly. Otherwise, you won’t be able to compare enough variants, making it less likely to find the best possible solution. In fact, the superior combination of accuracy and speed, powered by Cadmould’s proprietary 3D-F simulation algorithm, is one of the main reasons HellermannTyton relies on Cadmould.”

The Result: 60% Weight Reduction

This part exemplifies the distinctive results HellermannTyton can achieve for their customers. The smart, iterative, and cross-functional way of working helped HellermannTyton evaluate many design alternatives quickly and efficiently. The result reduced part weight by 60%, while continuing to meet the customer’s rigorous quality standards.

Real Results. Trusted Voices.

Customer stories and testimonials show how simulation turns challenges into measurable improvements.

Customer Story

60% Lighter, 100% Reliable

Through fast simulation-driven iteration, HellermannTyton engineered a charging socket holder that combines lightweight design with uncompromising accuracy.

Customer Story

Stacking Adapter Reimagined

How Plaston and Gollmer perfected a multi-brand toolbox connector with Cadmould and Varimos AI.

Customer Story

Getting Canister Lids Right The First Time

By combining simulation and modern measurement, Bergi-Plast improved closure quality, reduced scrap, and accelerated time-to-market.

testimonial

Cadmould stands out for its ease of use, fast processing, accurate results, and outstanding support. Its value for the price made it an easy choice for us.

Lutz Kreykenbohm

Manager Tooling & Plastic Technology

testimonial

Our collaboration with SIMCON has resulted in a 30% reduction in iteration cycles. I would unequivocally recommend Cadmould and Varimos AI without hesitation.

Alexander Wolf

Head of Plastic Competence Centre

testimonial

We opted for Cadmould Flex primarily because it allows us to perform multiple simulation runs simultaneously, ensuring both rapid results and high accuracy.

Amadeus Langeloh

Design Engineer

testimonial

Over two years, Cadmould optimized gating, controlled warpage, and prevented air entrapment for critical galvanized parts.

Michael Stenger

Development

testimonial

Easy to use, fast processing, and an intuitive interface—plus quick results, most of the time. Simulation moves us forward and is a lot of fun!

Philipp Beckel

Project Management

testimonial

Cadmould is fast and ideal for early geometry validation. It optimizes mold projects by cutting costs, reducing scrap, and ensuring high-quality parts.

Fabiano Rubio

CAE Applications Engineer

testimonial

Cadmould's Varimos AI add-on simplifies advanced Design of Experiments, optimizes process parameters, enhances efficiency, and improves part quality.

Govindraj Tantri

Engineer, Product Design

Need help?

We’ll connect you with the right expert!

At SIMCON, we ensure you get what you need—technical advice, commercial guidance, or just answers to your questions. Book a 1:1 consultation to explore our plans or schedule a product demo with a sales engineer. Whatever you need, we’re here to support you.