Simplifying Molding of High-Stress Parts

Where High Demands Meet Precise Solutions

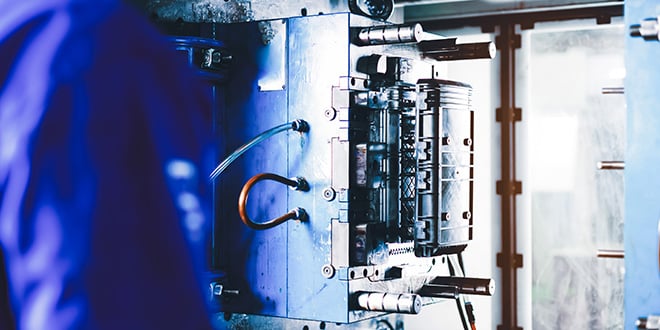

Gears, housings, and multi-component parts place high stress on molds - and on injection molders.

High Stress On Molds, Decreased Mold Lifetimes

Trial and Error Means Time and Money

Not All Machines Are Made Equal

Multi-Component Systems, Increased Complexity

High Stress On Molds, Decreased Mold Lifetimes

Trial and Error Means Time and Money

Not All Machines Are Made Equal

Multi-Component Systems, Increased Complexity

From Simulation to Calibration: Mastering Industrial Molding

SIMCON supports industrial part manufacturing by enabling you to anticipate issues and make adjustments early. From simulating multi-component molding to automating machine calibration, Cadmould Flex and its AI assistant, Varimos AI, help you optimize processes, reduce mold wear, and save resources.

Protect Your Mold. Preserve Your Performance.

Validate Early. Launch With Confidence.

Know The Limits. Run It Correctly.

Mastering Multi-Component Molding

Insights, innovations in injection moulding, webinars, and events.

Loreum ipsum, innovations in injection moulding, webinars, and events.

-

Complex part geometries requiring precise moulding techniques

-

Stringent quality and safety standards that demand high accuracy

-

Weight reduction initiatives to enhance fuel efficiency and sustainability

Real Results. Trusted Voices.

Customer stories and testimonials show how simulation turns challenges into measurable improvements.

60% Lighter, 100% Reliable

Through fast simulation-driven iteration, HellermannTyton engineered a charging socket holder that combines lightweight design with uncompromising accuracy.

Stacking Adapter Reimagined

How Plaston and Gollmer perfected a multi-brand toolbox connector with Cadmould and Varimos AI.

Getting Canister Lids Right The First Time

By combining simulation and modern measurement, Bergi-Plast improved closure quality, reduced scrap, and accelerated time-to-market.

We’ll connect you with the right expert!