Webinars and videos

Expand Your Knowledge of Cadmould and Injection Molding

Upcoming webinar

From Colors to Clarity – Interpreting Simulation Results Like a Pro

Running a simulation is only the first step. The real value lies in your ability to interpret the results accurately and translate them into actionable process improvements. In this "Deep Dive" session, we move beyond the basics of generating colorful plots to mastering the art of result interpretation within Cadmould Flex. This webinar is designed for beginners and engineering professionals who want to bridge the gap between theoretical data and real-world manufacturing success. We will guide you through the critical metrics that turn simulation results into a compass for your injection molding process.

Fundamentals

Upcoming webinar

Lorem ipsum dolor

Today, a leading technology firm announced a revolutionary advancement in artificial intelligence. Today, a leading technology firm announced a revolutionary advancement in artificial intelligence.

Mould optimization

Past webinars and videos

Cadmould V17.1 Uncovered: Insights, Context, and Practical Expertise

Explore Cadmould V17.1’s new tools and expert insights to improve simulation in complex production environments.

Software Updates

What’s New in Cadmould V17: Feature Deep Dive

Learn how Cadmould V17 improves multi-shot simulations with new rotate, mirror, and copy tools plus live Q&A.

Software Updates

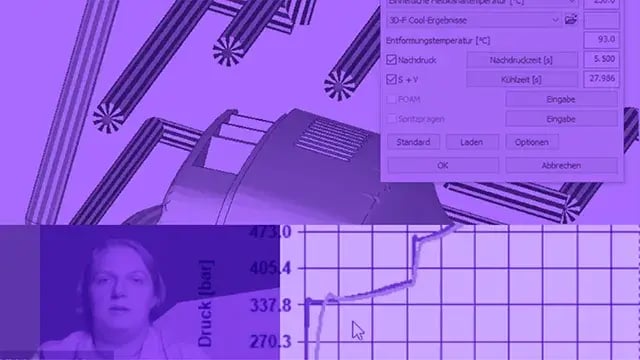

What’s New in Cadmould V16: Feature Deep Dive

Explore key V16 features: Report Wizard, faster solver, Excel integration in Varimos AI, plus feedback session with expert Angela Kriescher.

Software Updates

What’s New in Cadmould V15: Feature Deep Dive

Angela Kriescher presents V15’s faster optimization, new material database, VGMetrology support, fine STL export, and nozzle control improvements.

Software Updates

What’s New in Cadmould V14: Feature Deep Dive

Angela Kriescher highlights V14’s faster CAD imports, runner geometry use, weld line visualization, and improved simulation tools.

Software Updates

What’s New in Cadmould V13: Feature Deep Dive

Angela Kriescher presents 3D volume simulation, direct CAD cooling channels, enhanced Varimos AI usability, and new Ansys & VMAP interfaces.

Software Updates

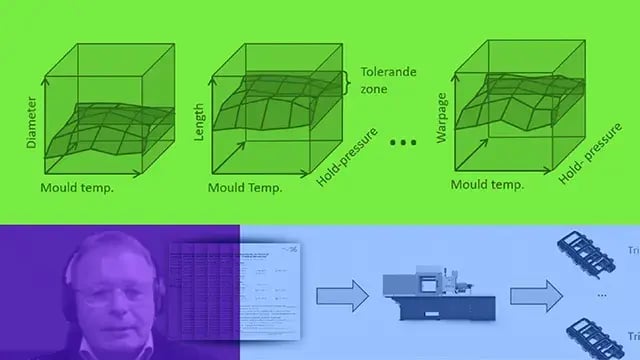

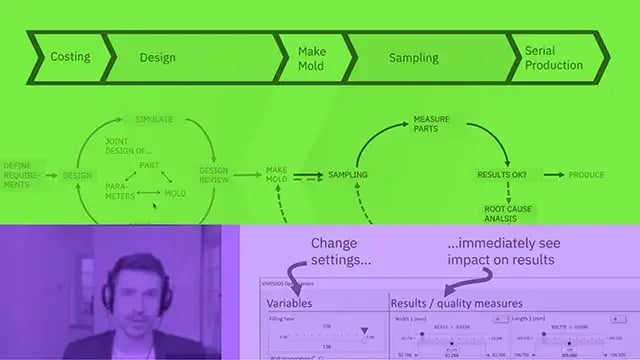

Improving Process Reliability in Injection Molding – with Digital Twins and Simulation

Learn how to define key process parameters early using Cadmould, Varimos AI, and T-Box for cost and quality control.

Cost Planning

Mastering Price Negotiations with Simulation and Cost Modeling

Patrick Dauser explains cost drivers and cycle time effects using Cadmould and PCC tools for confident price negotiations.

Cost Planning

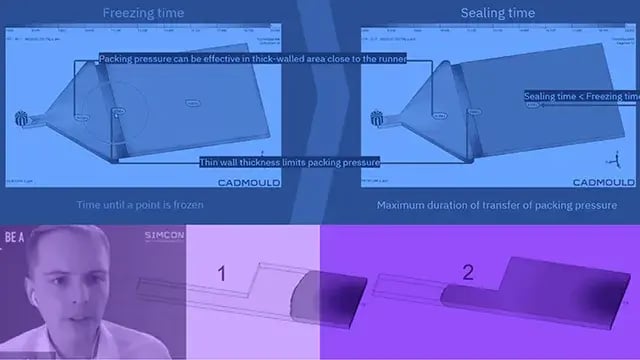

Minimizing warpage: How to refine your packing pressure profile

Explore packing pressure profiles and optimisation strategies to reduce warpage and improve part quality using Cadmould and Varimos AI.

Fundamentals

How to optimize packing: Reduce warpage with simulation

Angela Kriescher explains how to adjust packing profiles to reduce shrinkage, lower clamping forces, and improve part quality.

Fundamentals

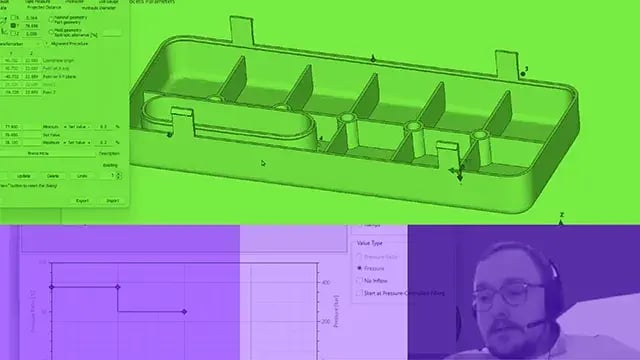

Improving dimensional accuracy by optimizing the packing pressure phase

Learn how to set packing and cooling times, avoid residual stresses, and adjust gate position and wall thickness for stable parts.

Fundamentals

Faster filling optimization with simulation-based DoE in Cadmould and Varimos AI

Franz Becker explains how to optimise filling balance, clamping force, and air traps without costly trial and error.

Fundamentals

Choosing the Right Mesh: When to Use 3D-F vs. 3D-V in Cadmould

Discover how 3D-F and 3D-V differ, when to use each, and tips on meshing, runtimes, and part geometry considerations.

Fundamentals

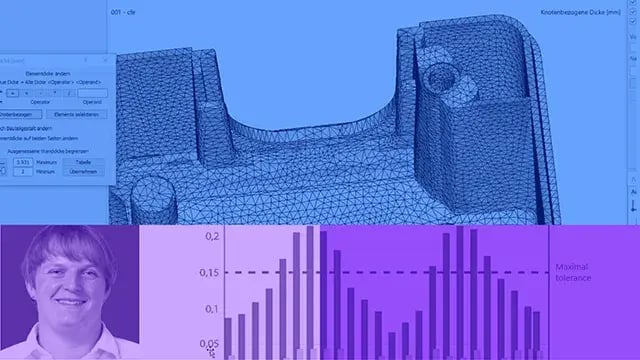

How to optimize wall thickness for robust, well-filled parts

Learn how to adjust wall thickness to improve flow, weld line position, and shrinkage without returning to CAD each time.

Fundamentals

Boosting Crash-Test Accuracy with Fiber Orientation Data

Experts show how precise fiber orientation improves crash-test predictions, boosting stiffness by 27% and strength by 18%.

FEM Analyses

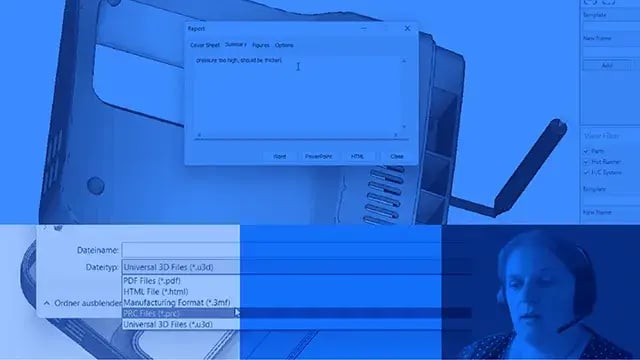

Introduction to the Report Wizard in Cadmould

Julius Kaschub shows how to automate and customise PowerPoint reports from simulation data for smoother workflows.

Reporting

Standardizing Simulation Reports at Audi – with the Report Wizard in Cadmould

Audi and SIMCON show how Cadmould’s Report Wizard creates consistent TAPE-standard PowerPoint reports, saving time and reducing errors.

Reporting

Clearer simulation reports, faster – directly from Cadmould

Learn to create clear, custom PowerPoint reports from Cadmould with automatic updates to save time and reduce errors.

Reporting

From simulation to machine: How digital connectivity accelerates setup

Learn how to connect Cadmould simulations to machines for optimized parameters and improved first-shot quality with digital feedback loops.

Tool and Machine

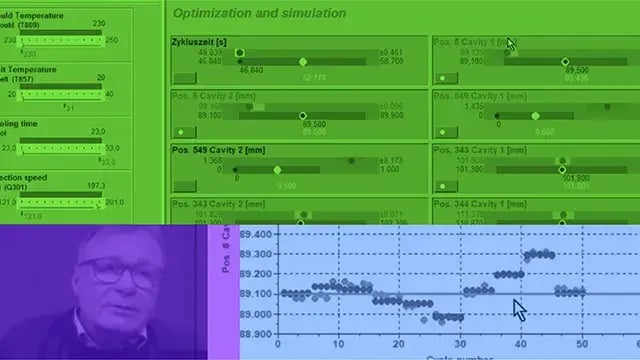

Smarter Sampling with Varimos Real: Optimize your process, not just parameters

Discover how Varimos Real uses real data, DoE, and AI to streamline tool validation and reduce trial-and-error cycles.

Tool and Machine

Optimizing Existing Injection Molds: Identify and Fix Hidden Weak Points

Learn to detect and fix sink marks, warpage, and weld lines by simulating process tweaks without changing the tool.

Tool and Machine

Better process settings with fewer tryouts: Data-driven optimization with Varimos Real

SIMCON experts show how Varimos Real uses DoE to optimise process windows, reduce tryouts, and improve injection molding quality.

Tool and Machine

Faster cycles, better settings: How to validate process windows with Varimos Real

Learn how Varimos Real guides systematic mould tryouts to identify stable, high-quality process windows and reduce guesswork.

Tool and Machine

How to correctly transfer machine parameters into your simulation

Learn how to convert real machine parameters into meaningful simulation data and understand their impact on results.

Tool and Machine

Simulation as a key enabler for hybrid lightweight structures in series production

Learn how simulation helps design and produce hybrid parts, modelling interfaces and reducing warpage and correction cycles.

Special Processes

Avoiding pitfalls in cascade injection molding: Practical insights from simulation and real-world cases

Learn to avoid weld lines, reduce clamp force, and balance filling using Cadmould in real-world cascade injection moulding cases.

Special Processes

Using Simulation to Optimize Gas Injection Molding Processes

Learn how Cadmould simulation helps balance runner systems to prevent pressure imbalances, uneven shrinkage, and clamping issues.

Special Processes

Balancing Runner Systems: Improve Filling, Stability, and Part Quality

Discover how Cadmould helps prevent pressure imbalances and uneven shrinkage through optimized runner and gate design.

Special Processes

How to reduce warpage through smarter thermal design

Julius Kaschub explains how to automate simulation and analysis for less warpage, shorter cycles, and robust injection processes.

Thermal Analyses

How digitalization is transforming your role in injection molding

Bastiaan Oud discusses how digitalisation changes workflows and why adaptability is key for plastics engineers’ success.

Career

Filters

Need help?

We’ll connect you with the right expert!

At SIMCON, we ensure you get what you need—technical advice, commercial guidance, or just answers to your questions. Book a 1:1 consultation to explore our plans or schedule a product demo with a sales engineer. Whatever you need, we’re here to support you.