Injection Molding for the Future

Mastering Bioplastics, Recycled Materials, and Lightweight Structures

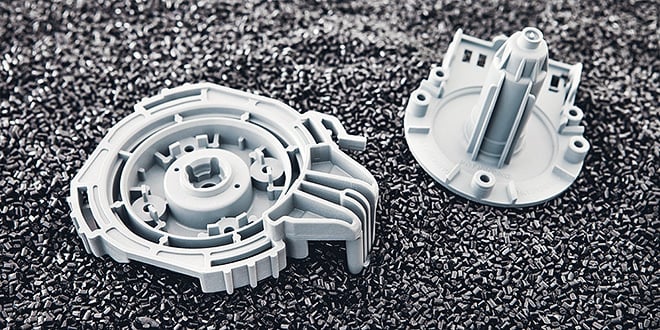

Molding with sustainable materials means navigating inconsistent recycled content, hybrid lightweight structures, and complex flow behaviors in bioplastics—all while meeting waste and lifecycle targets. For injection molders, it’s a true test of process control.

Taking a Chance on Bioplastics

Getting To Know Non-Virgin Materials

Mastering Modified Properties in Lightweight Parts

Reducing Waste and Improving Energy Efficiency

Taking a Chance on Bioplastics

Getting To Know Non-Virgin Materials

Mastering Modified Properties in Lightweight Parts

Reducing Waste and Improving Energy Efficiency

From Bioplastics to Hybrids: Molding with Confidence

The Cadmould simulation ecosystem takes the guesswork out of molding biomaterials, recycled plastics, and lightweight hybrid components with inserts. By simulating and optimizing mold and process design before production, you get high-quality, lightweight, sustainable parts while reducing waste and energy consumption.

Sustainable Materials, Reliable Results

Durable Materials, Seamless Processes

Lightweight Parts That Perform Like Heavy-Duty Parts

Less Waste. Less Energy. More Control.

Insights, innovations in injection moulding, webinars, and events.

Loreum ipsum, innovations in injection moulding, webinars, and events.

-

Complex part geometries requiring precise moulding techniques

-

Stringent quality and safety standards that demand high accuracy

-

Weight reduction initiatives to enhance fuel efficiency and sustainability

Real Results. Trusted Voices.

Customer stories and testimonials show how simulation turns challenges into measurable improvements.

60% Lighter, 100% Reliable

Through fast simulation-driven iteration, HellermannTyton engineered a charging socket holder that combines lightweight design with uncompromising accuracy.

Stacking Adapter Reimagined

How Plaston and Gollmer perfected a multi-brand toolbox connector with Cadmould and Varimos AI.

Getting Canister Lids Right The First Time

By combining simulation and modern measurement, Bergi-Plast improved closure quality, reduced scrap, and accelerated time-to-market.

We’ll connect you with the right expert!